.

SUPREME POWER IS A UNITRONIC AUTHORIZED DEALER !!

It's time to combine the unmatched customer service and established industry experience of Supreme Power with the performance, power and reliability of Unitronic software and hardware.

This will be our platform specific thread for all Unitronic software & hardware so stay subscribed!

**B9 S4 & S5 SOFTWARE IS UNDER DEVELOPMENT AND DUE OUT SOON**

.

.

Unitronic's Performance Software is programmable directly through the OBD-II port and is UniCONNECT+ compatible. Within minutes, Clients can enjoy a total night-and-day driving experience.

UniCONNECT + is Unitronic's End-User Programming and Diagnostic Interface, which provides its Clients the freedom to flash their Engine Control Unit (ECU) from the comfort of their home or garage. It is no longer necessary to schedule an appointment at an Authorized Unitronic Dealer to have your Performance Software installed, removed, upgraded or reflashed. UniCONNECT + empowers its Unitronic Performance Software Clients with the freedom to tune their vehicle at their will.

FEATURES

Engineered with Strict Industry Standards

With over 10 years of experience with Bosch and Siemens engine management systems and calibrations, Unitronic is able to utilize its expertise, industry leading tools and equipment to ensure an optimal calibration; delivering maximum performance, while maintaining complete OEM-like reliability and drivability.

Extensively Tested Under Various Driving Conditions

Development begins using Unitronic’s in-house Maha Chassis dyno housed in an environmentally controlled cell; closely monitoring a plethora of operational data, utilizing industry leading calibration tools and resources. Beta calibrations are then tested in street and track scenarios, using multiple cars under various driving conditions. This engine calibration strategy ensures Unitronic Performance Software delivers maximum performance, OEM-like drivability and reliability anywhere in the world. Unitronic Performance Software is only released to its Clients once development is thoroughly completed in accordance to Unitronic’s strict standards.

Factory Safety Limiters Retained

OEM “fail safes” are retained within the ECU calibration. Close monitoring of all operation parameters ensures that engine operation stays within factory components limits, resulting in reliability.

Optimized Responsiveness, Smoothness, Drivability, and Comfort

Unitronic’s ECU calibrations are engineered to improve engine response and reduce low-end lag. Unitronic’s Performance Software has gained worldwide recognition and is well known for its broad powerband, with smooth power delivery, maximizing responsiveness and “area under the curve”, under normal and hard acceleration.

Optimized Maximum Output

Unitronic’s ECU Calibrators deliver the maximum power output while staying within the operational limits of the factory engine and drivetrain components. Specifically, this results in the highest engine performance without sacrificing the reliability of the engine, turbocharger, or other engine and drivetrain components.

Power Delivery Perfectly Optimized Throughout the Power Band

Aligned with the OEM strategy, the calibration is designed to offer a large flat torque plateau to provide a smooth and linear power band. Maximum torque output is achieved sooner and maintained longer which creates a broader torque plateau and greater area under the curve. This results in an improved acceleration and optimal engine operation.

Improved Fuel Efficiency

Optimized timing and injection in cruising condition allows for an improved fuel efficiency, under normalized driving conditions.

Ignition Timing Precisely Calibrated for Higher Octane Fuel

Engine calibration optimized to take advantage of higher fuel quality to extract maximum energy from the combustion. Therefore, when using a higher octane fuel, more power and better fuel efficiency will be achieved.

- - - Updated - - -

Unitronic® is proud to release its Intercooler Upgrade for the B9 Audi® S4® and S5® equipped with the 3.0 TFSI® EA839 engine. This direct OEM replacement bar and plate intercooler provides a dramatic reduction in charge air temperatures to ensure peak performance is achieved and sustained while resisting heat-soak after repeated efforts and in harsh climates and conditions.

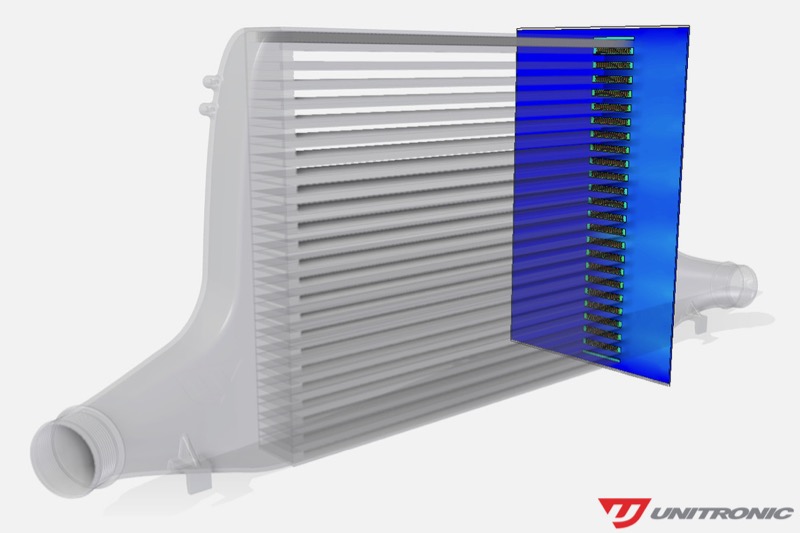

Consistent with all of its performance products, Unitronic utilizes only the latest industry leading tools, equipment and computer aided design software that are packed with the latest technology from our technology partners at Creaform® and Stratasys®. These tools and technology help to achieve a design that not only optimizes thermal efficiency, but airflow to maintain the least amount of pressure drop, while fitting within the space constraints without affecting the frontal crash bar assembly or other components behind the front bumper.

At Unitronic, development begins with setting the objectives; performance, efficiency, aesthetics and quality. Operations start with 3D scanning the 3.0 TFSI engine bay and OEM components with its in-house 3D scanner. Once 3D scan data has been collected and processed, Unitronic Hardware Engineers then interact with the 3D models to identify fitment constraints, mounting locations, other component locations, etc. to ensure the final product fits perfectly within the “envelope”.

Design and Engineering begins with the evolution of the design in meeting the objectives. Criteria from a top level is first met with the platform's design constraints; breaking it down to the details in optimizing the design. With upfront engineering fluid dynamics (EFD), Unitronic is able to hone in and refine the areas that are most effective in meeting those objectives.

With the ability to perform different iterations from design changes we are also able to accurately predict performance on how the design will perform. Above is a predictive simulation plot operating within the same conditions it was tested in. Results illustrate and validate the actual data collected.

Using EFD simulations, Unitronic is also able to predict the thermal exchange of the intercooler core in the wake of air passing through the channels. This provides further information on how our design will impact the efficiency of the engine and a/c radiator.

Unitronic's bar and plate intercooler core features a unique staggered and louvered fin configuration to maximize efficiency, significantly reducing charge air temperatures allowing for cooler, more dense air to be inducted by the engine; ultimately resulting in an increase in engine performance.

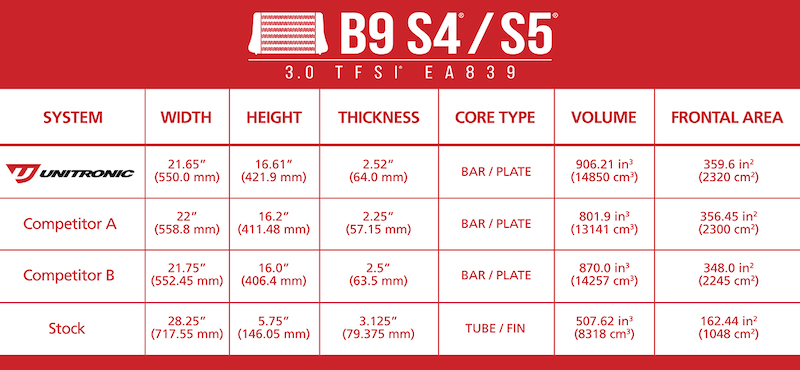

When intake air temperatures reach a specific threshold, the engine control unit begins to compensate to account for the air temperature, resulting in a decrease in performance. Unitronic's core measures 21.65” x 16.61” x 2.52” (550.0mm x 421.9mm x 64.0mm), a 79% increase in volume over stock, allowing for a greater volume of air to exchange heat, which, combined with a proper fin configuration, allows for maximum efficiency and reduction in heat-soak thresholds without producing a significant pressure drop.

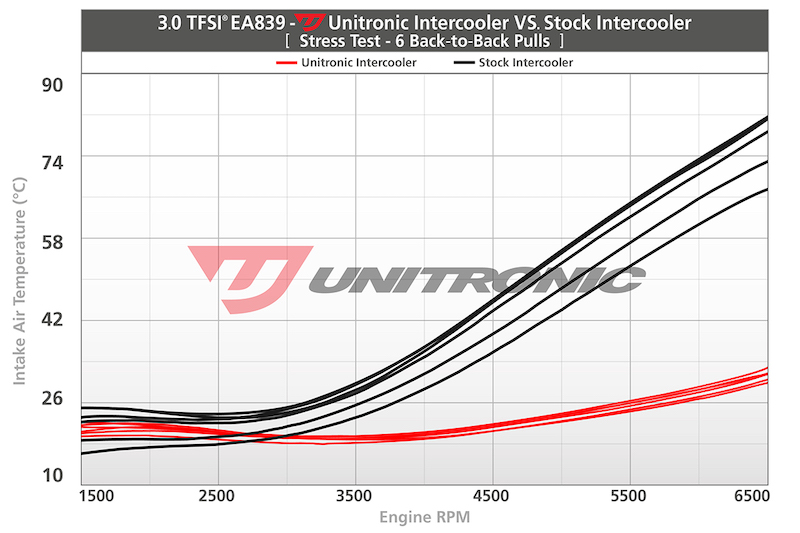

Utilizing its own B9 Audi® S4® for research and development provided Unitronic with an in-house platform to run through testing. Data was collected on its in-house MAHA Chassis Dynamometer, using our standard cooling fans with ducting properly aligned with the front end of the vehicle. The vehicle's front bumper/fascia was fully affixed for all tests. All data was collected on the same day, starting with the OEM intercooler testing first.

Ambient air temperature was stable at 63°F (17°C) throughout the day. Testing consisted of 6 consecutive dyno pulls with a 20 second pull and a 30 second cool down period in between runs, with both the OEM and Unitronic Intercoolers to collect intake air temperatures to provide data on cooling abilities, efficiency, and resistance to heat soak compared to the OEM unit.

The graph above shows the Intake Air Temperature for both the OEM and Unitronic Intercoolers, individually for each of the 6 runs. The Unitronic Intercooler provided significant reductions in air temperature resulting in a cooler, denser charge air being ingested by the engine, resulting in increased performance. Its resistance to heat soak means that the core retains its cooling abilities, even though the most rigorous of conditions.

Entering and exiting the core is an important aspect that should not be forgotten about. With airflow and fitment implications, Unitronic went through many end tank prototypes and production samples prior to approving this Intercooler for production. Unitronic's cast Aluminum end tanks are designed with tolerances of +/- 0.020” to ensure perfect fitment across all of our production units. Inlet and outlet design has also been optimized to ensure smooth airflow through the intercooler and features barbed/serrated bead rolled machining to ensure the charge hoses stay securely affixed.

Like all Unitronic Performance Hardware, this Intercooler offers direct bolt-on fitment, retaining the factory mounting locations in order to simplify the installation process.

FEATURES

• Highly efficient bar & plate intercooler core

• Drastically reduces charge air temperature for cooler, more dense air

• Significantly more resistant to heat-soak

• 79% more volume than OEM (Unitronic Core Dimensions: 21.65” x 16.61” x 2.52” / 550.0mm x 421.9mm x 64.0mm)

• Cast Aluminum end tanks

• Direct OEM replacement; no bumper, radiator support, or other trimming required

APPLICATIONS

2017-2019 Audi S4 3.0 TFSI

2017-2019 Audi S5 3.0 TFSI Coupe and Sportback

💥AVAILABLE NOW -*Unitronic Performance Software for B9 S4, S5 and SQ5 3.0TFSI EA839, OBD2 Port Compatible with UC+💥

Unitronic® Performance Software is now available for the B9 S4®, S5® and SQ5® equipped with the 3.0TFSI EA839 (CWG) engine. With testing and validations completed, power outputs are increased by up to +103HP/ +121LB-FT with Unitronic Stage 1+ 93octane/98ron Performance Software for a maximum of 454HP / 481LB-FT. Unitronic is also proud to announce this software upgrade is entirely compatible with its UniCONNECT+ cable, empowering Clients to tune their vehicles themselves directly through the OBD-2 port within minutes, from the comfort of their own home or garage.

With baseline figures and data acquisition completed in stock format, Unitronic interprets the data and recalibrates the Bosch MG1 engine control unit equipped on the B9 S4, S5 and SQ5 to achieve optimal performance through an increase in boost, optimized ignition timing, lambda, camshaft timing, and much more. Research and development of Unitronic’s Performance Software continues with further dyno, track, and road testing, while closely monitoring running conditions through high-speed data logging tools and equipment to ensure maximum performance is achieved, while maintaining complete OEM-like reliability and drivability.

After extensive development time and countless hours of flash protocol testing, a multitude of empirical data is collected from around the world. Once a thorough analysis is completed, Unitronic calibrators develop the Performance Software which is fully optimized for maximum performance while staying within the constraints of the OEM hardware to ensure reliability and drivability are maintained. This results in Stage 1 (91 octane/95 RON) and Stage 1+ (93 octane/98 RON) ECU calibrations fully supported by Unitronic's UniCONNECT+ cable.

Unitronic is committed to continuing development of the 3.0TFSI EA839 engine platform found in the B9 S4/S5 and SQ5, with plans to roll out additional fuel support for E85 and Race Gas in the near future.

Unitronic's Performance Software is optimized for use with Unitronic's Carbon Fiber Intake System and Intercooler Upgrade.* For best results, Unitronic strongly recommends these hardware upgrades to achieve advertised power figures. Without these hardware upgrades, users can expect a loss of up to 20HP.

[/LEFT][/LEFT][/B]

Reply With Quote

Reply With Quote

Bookmarks