I am confused as to why people are associating wastegate rattle with a certain downpipe? We have dealt with wastegate rattle from factory vacuum-actuated turbos for going on 8 years. The reason people are associate more rattle with a downpipe is simply that you can hear it more clearly with the stock DP removed, the downpipe itself has nothing to do with wastegate rattle.

We make multiple pieces of hardware to address it. The BMW N54 is notorious for it. So bad BMW issued many many many updates to try to fix it.

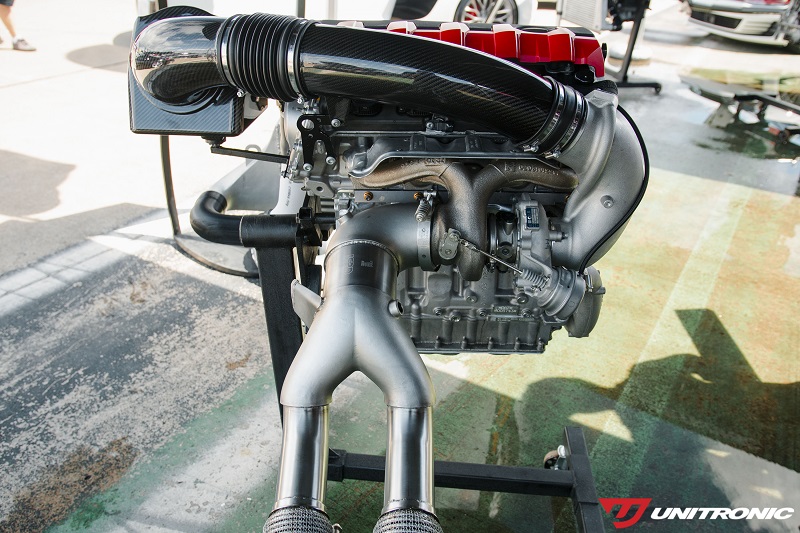

The bottom line on wastegate rattle on a vacuum-actuated turbo is as follows. 1. The assembly itself can be about 20-25% of the problem. On the BMW's the design was terrible which caused some tendency to rattle. The Borg-Warner unit on the RS3 has a very well designed flapper with multiple strategies in place for the sole reason of eliminating rattle. For the Audi, I would say 0% of the problem is the flapper itself. For the BMW's the other 75-80% was simply the flapper position in relation to the turbine housing, which would be 100% on the Audi since the flapper itself is such a good design. If the DME is holding the flapper just off the housing on idle, decel, off-throttle etc. The high-speed exhaust is coming through there and causing vibration, and in return rattle. Think of a balloon when you squeeze the end and let the air out.

The remedy is extremely simple. In all of the BMW tunes, you have an adjustable default wastegate position or a simple rattle fix checkbox. This allows you to adjust your flapper position in relation to the housing, open it a little more rattle is gone as it has nothing to rattle against, close it more, and it's gone because if it's against the housing with some force it also cannot rattle.

Rattle can be easily fixed on this platform same as it was on the N54 but no hardware is even needed, just some minor adjustments to the wastegate position tables in the tune.

JB4 wastegate.jpgMHD Slider.jpg

Reply With Quote

Reply With Quote

JHM SC'ed / 08 Evolution X (full bolt on) / 05 M3 Dinan SC'ed / 05 LGT w/ Hybrid Turbo ......and many others!

JHM SC'ed / 08 Evolution X (full bolt on) / 05 M3 Dinan SC'ed / 05 LGT w/ Hybrid Turbo ......and many others!

Bookmarks