Car info: 2000 A6 avant Quattro 2.7T, 1BA = Standard suspension/shock absorption, 282000km(175000miles)

Here the other day I replaced the inner tie rod on the steering, and did an alignment.

This is why i replaced the inner tie rods: https://youtu.be/22xik4Ovue0 moves very easy, bot couldn't feel any movement. (they where not part of the meyle kit i used when replacing all the rest)

I put the car on the garage floor, ligned up to strings of sewing thread and tried to get the car as parallell as I could with the strings.

First, some rough adjustment:

and after rough adjustment:

The inner tie rods where a bit different from the original(the clamp on the booth didn't hold, so used some cable ties), cheap from JP group, let's see how long they last.

Stringing process:

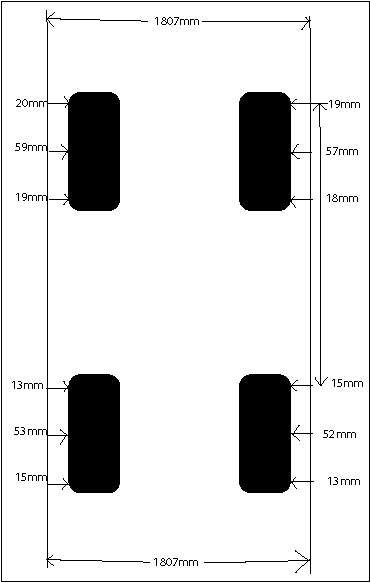

Measurement, on front and back side of the rim:

Measurements:

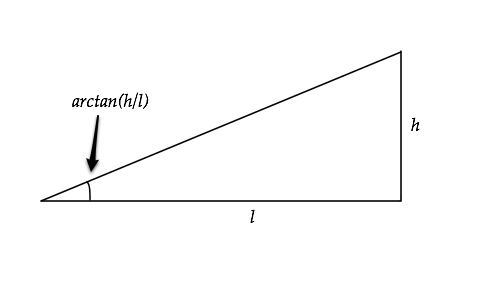

Formula for calculating the angles:

Since the rim is 500mm long, and with my measurements of 1mm different on the front, and 2mm on the back, it gives:

1mm = 0.11 degree

2mm = 0.23 degree

Toe in front according to bentley: +0.11+-0.02 degree

As seen on the measurement, the rear is pointing a bit to the right in the same direction, the car wasn't perfect parallell to the strings, but as close as I bothered taking it. The measurements on the centre of the wheels are taken from the string to the heads of the wheel bolts.

May need to adjust the rear.

Also, I didn't measure the lengt bethween the wheels on each side, going to do that also sometime, to check if the subframe in the front is a bit rotated.

The camber was 0.7 degree on the left front, and 0.4 degree on the front right, which is within spec, but indicates that the subframe should be shifted a bit to the right. (0.5+-0.25 is spec)

Conclusion: it is no problem doing the alignment yourself, by measuring the difference on the front and back of the rim, if the difference is 0.5mm you have 0.057 degree.

Any hints or tricks or inputs?

And, how much difference is there in the witdh of the wheels on the front and back axis? Found this on some site: front trail:1540mm, rear trail: 1569mm, difference: 29mm, I got: 11mm.

Reply With Quote

Reply With Quote

Bookmarks