My injector wires were pretty beat up after 160k miles, and the last time I had my injectors out, after I reconnected the wiring harness my car shot a flame in my garage. The wiring harness was shorting so it was time to fix it. I wanna thank Lysergik for his DIY, I took inspiration from that, but I went a slightly different route and wanted to share. For my build, I am using EV14 Bosch injectors. So I opted to go with USCAR EV14 connectors, rather than going with oem injector connectors and using the EV14 adapter. My new harness will directly connect to the EV14's.

Depending on your specific case, you might want to reuse the OEM injector clips, but just get new terminals that you can attach to the new wiring you will make.

Original DIY

http://www.audizine.com/forum/showth...or-Harness-DIY

*Disclaimer: I am not responsible for you messing up your ECU by improperly wiring this harness. Do this at your own risk and if you have any questions please ask!

So here's what you'll need:

Links for everything:

Crimp tool

Wire stripper

Braided sleeve 1/4"

Braided sleeve 1/2"

Heat Shrink

Self-Fusing Tape

18AWG TXL Wire (You can also use 20gauge)

12-pin sealed connector

EV14 specific connectors

If you are using OEM style injectors:

OEM injector terminals

OEM rubber boots

De-pinning tool

You'll also need a heat gun for the heat shrink tubing

You're looking at about $100 in damage for the parts. Not bad for peace of mind and a nice looking harness.

Ok so now we're ready to get started. I WILL SHOUT LIKE THIS FOR IMPORTANT STEPS

First step is to DISCONNECT YOUR BATTERY. Then pop the hood and start disconnecting your harness. Find your cam position sensor (front of engine, right side of timing cover) connector and push in on the metal tab to release the connector. Then move over to your fuel rail and locate the metal tabs on the back of the connectors. Push in on the tabs while you pull up gently. They'll release with little effort. After you have all four injector connectors off, as well as the cam sensor connector, you can start to fish the harness back towards the rear of the engine so you can have a bit more slack when cutting the wires.

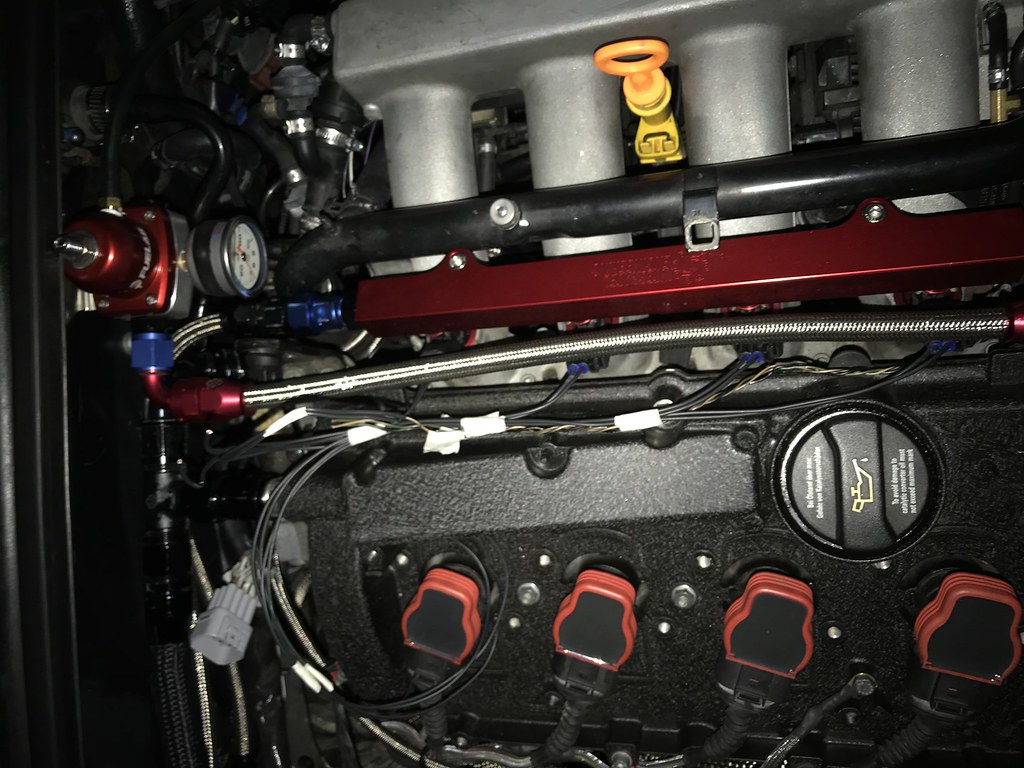

Here you can see the section you will be working on. I fished the harness back and under my valve breather so the whole thing can lay over the coil packs.

Using a sharp razor, begin cutting the black wiring cover to expose the 11 wires.

You'll wanna cut a bit more than the picture above, dont worry about exposing too much wire, you can always cover that up with heat shrink/self-fusing tape.

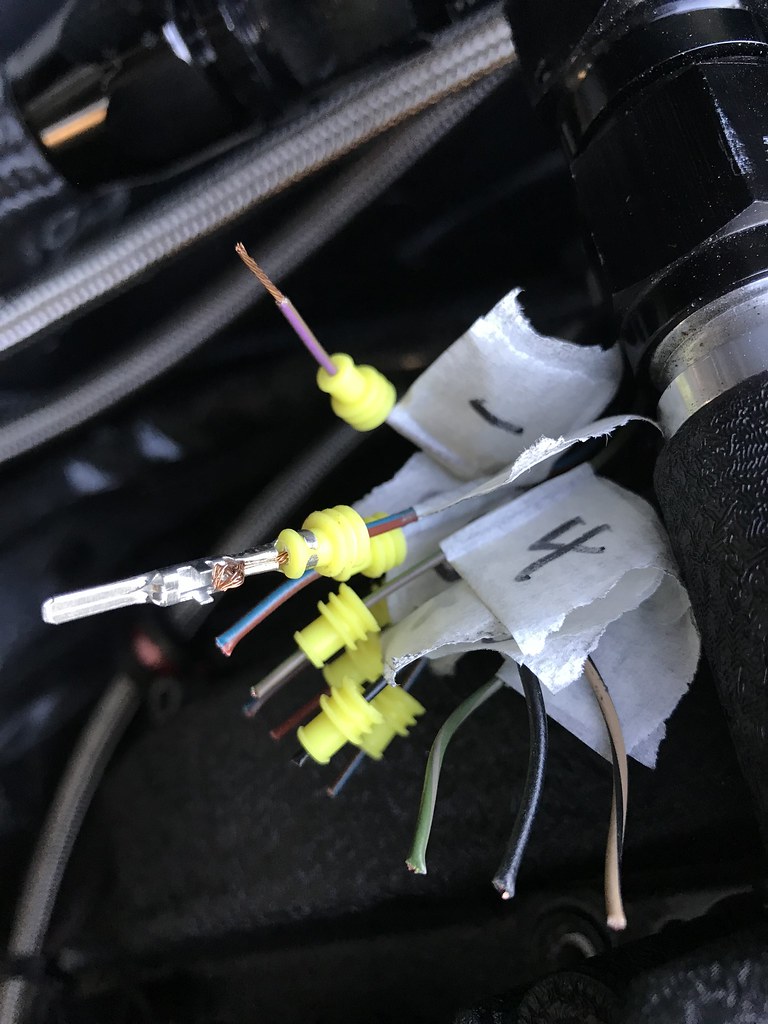

Once you have all the wiring exposed, grab some tape and stick two pieces on each wire, about 2 inches apart for a total of 22 pieces of tape. Then for each wire, mark the tape with the same number on both pieces. Take a look at wire #3, and do that for all 11 wires. This is crucial for determining which wires match up. You wont want to mess this step up.

Once you have them all labeled, you can cut the wires. Cut them all at the same length. If you grab all of the wires there shouldn't be any longer than the others. Now you can begin crimping on the male terminals. Strip the ends of the wires, and slide a yellow insulator over the wire, then use the crimp tool to attach the terminals to the wires. End result should look like this. Make sure you don't pull off any of the labels in the process!

Should look like this when you finish

Then grab your longer male end connector and insert the terminals into the back of the connector. They only go in one way, so make sure you twist the terminals to orient them properly. You need to hear a click to ensure the terminal is properly seated. Give each wire a little tug after you insert it to make sure its snug.

NUMBERING EACH CONNECTOR: You can insert the wires in whatever order you like into the connector. What I did was, when looking at the back of the connector, wire #1 went into the top-left slot. Wire #2 went to the right of that, and so on. Here is a diagram to help illustrate

Now that you have your connector attached to the wires in the engine bay, you can move onto making the new harness. Take the half of the oem harness that you cut off and lay it all out in front of you. There are two wires to each injector connector, and 3 wires going to the cam position sensor connector.

What I did was take my new injector connector, crimp on the new terminals and insulators, and take it back to the engine bay so I can mock it up and find the length I'd have to cut it. Do the same with the remaining injector connectors. SO, to make this all easier, assemble the new injector connectors with some extra length of wire attached. Then take them to the car and clip them into the injectors. Run the wires how they would be laid out and use some tape in various sections to secure the wires together. When you take it all back out you should have an idea of the lengths you'll cut all the wires to.

The white pieces of tape near the ends of the wires are how I marked the lengths.

I had to lengthen the wires for my cam position sensor, so I cut the green, beige, and black wires and attached longer pieces of wire. This might not be necessary for you. BE SURE TO LABEL THE NEW WIRE WITH TAPE JUST AS BEFORE

Now you can start putting it all together. After you have the lengths of all the wires down, you can slide some heat shrink over the wires. Bundle them together and cut some of the braided sleeves to fit over the wires. So in order it goes: wires, heat shrink, braided sleeve. You can then use the self-fusing tape to seal any connection points of the braided sleeve. MAKE SURE YOU LABEL THE NEW WIRES ACCORDING TO THE EXISTING LABELS WIRES COMING OFF THE OEM INJECTORS

Once you're done, crimp on the 11 female terminals to the new end of the harness. You should have all 11 labels still on the wires. YOU WILL NEED TO MIRROR THE POSITIONS OF THE WIRES FROM THE FIRST CONNECTOR YOU MADE. TAKE SOME TIME TO THINK ABOUT IT AND MAKE SURE YOUR NUMBERED WIRES WILL MATCH UP.

This is the finished product!

Congrats, you now have a working, good looking, and removable injector harness. Install back into the car, reconnect the battery, and start her up. If all is well, drink a beer

Reply With Quote

Reply With Quote

. I was not clear if you changed your fuel injectors from stock, or if those are the original connector types for the injectors that came with your engine. So I have 2-pin connectors with metal clips for my stock EV12 Fuel Injectors. I did find and buy some Bosch

. I was not clear if you changed your fuel injectors from stock, or if those are the original connector types for the injectors that came with your engine. So I have 2-pin connectors with metal clips for my stock EV12 Fuel Injectors. I did find and buy some Bosch

Bookmarks