TIME/DIFFICULTY

5-8hrs factoring in Murphys Law

Medium difficulty range

Must make your own special tool

PARTS

₪ Drive-Shaft Center Support Bearing***

₪ CV Gasket 183521141A x2

₪ CV Grease

TOOLS

[Key requirements]

- 10mm Socket

- 13mm Socket

- 28mm or 1-1/8 Socket

- 6mm Allen Socket

- T45 Torx Socket

- 3/8 Extensions

- 16mm or 5/8 Combination Wrench [to be modified]

- Large Flat-Head Screwdriver

- Angle or Bench Grinder

- Jack and Stands

[Basic necessities]

- a solid metric tool set

- Allen and Torx Socket sets

- 3/8 Torque Wrench

- Small Flat-Head Screwdriver

- Ball-Peen Hammer

- Vice Grip

- Tape Measure

- Razor Blade

- LocTite Blue or Red

- Paint Pen or Sharpie

[Misc.]

- Penetrating Spray

- Plastic Bags

- Shop Rags

***I bought mine from Colorado Drive Shaft. Call or email David. Very knowledgeable and outstanding person to do business with, his company has been rebuilding drive-shafts for 25 years with VW/Audi drive-lines being one of their specialties. Overall I was very impressed with the part and service.

SETUP/DRIVE-SHAFT REMOVAL

Apply hand-brake, raise car on jack stands.

Remove exhaust system from down-pipes.

Remove drive-shaft heat shield using a 10mm socket to undo the 4 fasteners.

Remove drive-shaft shield from transmission using a T45 Torx socket to undo the 2 screws.

Remove the 6 allen bolts from both CV joints using a 6mm Allen socket. Loosen 2 bolts then release hand-brake, rotate shaft, reapply hand-brake, loosen the next 2 bolts, repeat for last 2 bolts.

Dislodge the CV joints from the flanges using the rounded end of a Ball-Peen Hammer. A few sharp hits on the CV body will do the trick.

Unbolt the carrier and remove drive-shaft. Loosen the 2 bolts with a 13mm socket, when the bolts are nearly off - brace the carrier with one hand while removing the bolts with the other. At this point lower the drive-shaft on your chest and slip out from under the car.

Note: this step is better done with a second set of hands but youll miss out on some great theatrics.

Cover CV joints with plastic bags as soon as the drive-shaft is out.

Spray penetrant around the yoke bolt and let sit. Stand drive-shaft upright when doing this as to not let any of the liquid seep around the u-joint.

__________________________________________________

⚠ The next three procedures dont exist in any service manual because the carrier is Non-Serviceable as deemed by Audi. You are literally entering the Matrix of Audi repairs. With that said; this is my way, but its only one way, and though it worked for me, it might not work for everyone. The following should only be considered for reference and not rule.

SPECIAL TOOL/BOLT REMOVAL

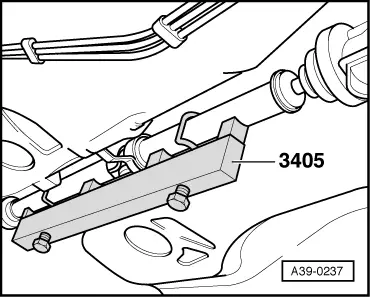

A 16mm or 5/8 combination wrench and an angle or bench grinder are needed. The tool will be made in 3 stages.

Stage 1

Grind the back of the wrench head as shown. If using a 5/8 wrench; trim the opening until it fits onto the 16mm bolt. Only remove enough material until wrench fits and has room to make an 1/8 turn to partially break the bolt free. Attach a Vice Grip on the yoke to hold drive-shaft in place.

Stage 2

After the bolt is partially broke free continue to remove more material. Start to grind a curve into the neck. Then turn bolt further.

Stage 3 Final Form

Now continue to remove more material as needed at the neck and head until bolt is able to be turned enough to allow the wrench to be moved back to its previous position to make another turn.

SHAFT SEPARATION

Make alignment marks on the yoke and shaft as shown. Its critical to make these marks as accurate as possible for rejoining later on. The drive-shaft can become out-of-balance even if off by only one spline.

Unthread bolt far enough out to wedge a large screwdriver at a slight angle between the yoke and bolt as shown [do not put any pressure on the u-joint itself], force pressure against the bolt and firmly hit screwdriver with hammer. As shaft begins to separate; unthread bolt further and keep repeating previous steps until fully split.

CARRIER INSTALLATION

Remove old carrier. Cut carrier frame off with a razor blade, place large flat-head screwdriver on carrier lip as shown, hit firmly with hammer until bearing comes off. Use caution as to not bend the shaft ridge.

Note: using a bearing splitter and press is ideal for this step and the next.

Install new carrier. The carrier goes on with the Cupped side facing up. A 28mm or 1-1/8 socket fits perfectly on the bearing race to act as a strike or press point. Fully seat bearing with a few light hits by hammer or press bearing in place.

Rejoin drive-shaft. First apply LocTite blue or red on bolt threads, align both ends of the drive-shaft with the marks made previously and slip splined ends together. Now thread then tighten bolt as much as possible.

Tip: holding bolt in place with a small flat-head screwdriver or pick will make getting the threads started much easier.

Now take time to look over the drive-shaft and admire your work.

__________________________________________________

DRIVE-SHAFT REINSTALLATION

Clean and grease both CV joints and install a new gasket on each flange.

Install drive-shaft in the reverse order of removal.

Torque CV joint bolts in a star pattern to 41ft-lb [55nm].

Perform alignment [see Alignment in the next section].

Torque carrier mounting bolts to 18ft-lb [25nm].

Give the shaft a few spins while inspecting your work.

ALIGNMENT

Turn shaft until the yoke off the carrier is perfectly horizontal, now measure from the center of the u-joint cup to the ridge of the opposing yoke on both sides as shown. Slide carrier side-to-side as needed until the measurements become equal on both sides of the yokes. Tighten carrier mounting bolts, spin shaft, check measurements, and make adjustments as necessary until measurements are perfectly equal. At this point the drive-shaft is aligned.

FINAL DETAILS

Reinstall drive-shaft heat shield

Reinstall exhaust

Lower off jack stands

Take a test drive

Yell out the window I am Ze άbermensch!!!

Reply With Quote

Reply With Quote

Bookmarks