Any point in change?

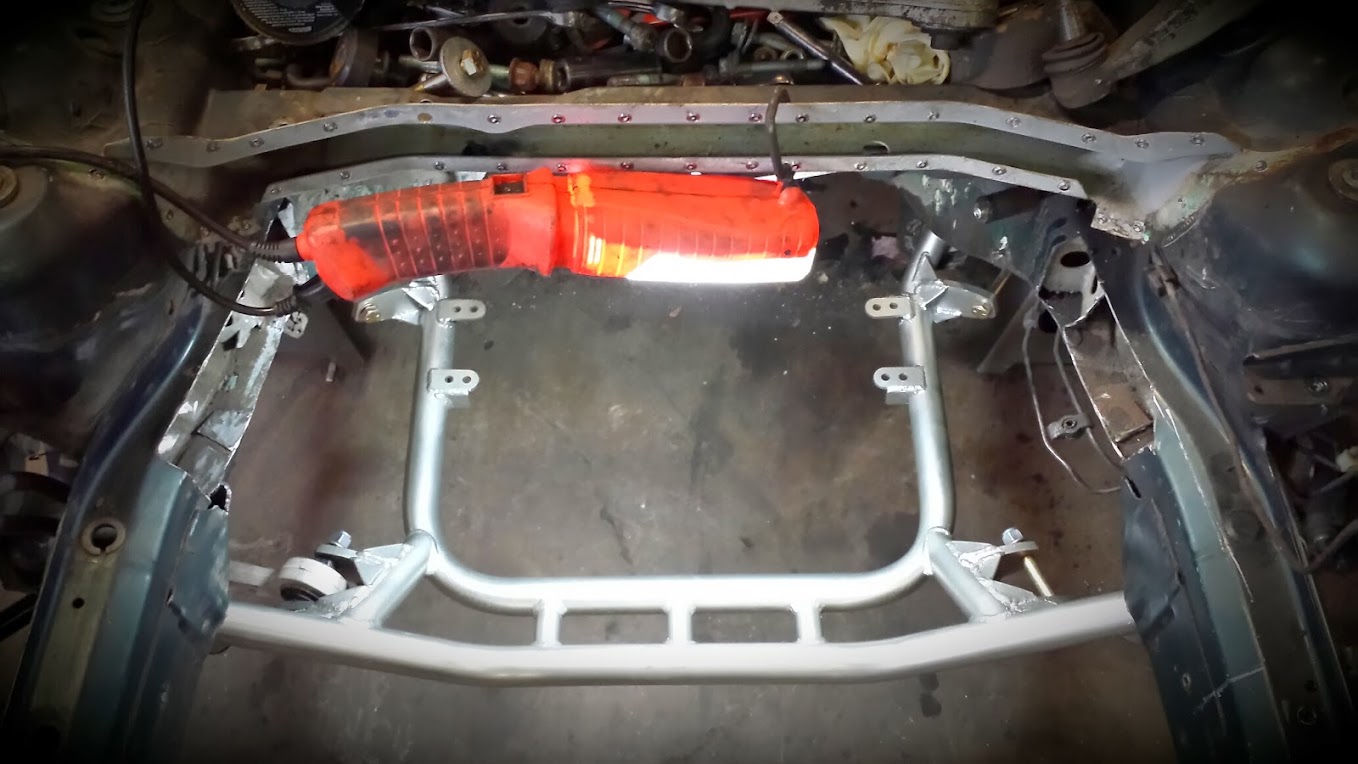

Supposedly lighter,

stronger

stiffer, more responsive

customizable suspension geometry

Maybe it's not stock because OEM was easier/cheaper/faster?

stamped + spotwelded (robot) sheetmetal(?) vs aluminum, chromoly, etc.?

D3 A8 rear (4E0 505 235 H) looks the most similar, maybe it can be made to fit?

OEM B6 = 8E0 505 235 BP

as we know, a lot of VAG parts are interchangeable like legos, sharing the same parts bins, platforms, etc.

FWIW, D3 A8/S8 r.Diff looks the same as ours..Maybe the body connection points are too - if not, cut and weld?

vs. B6 diff:

E39 M5:

C5 RS6:

Phaeton:

Passat 4motion:

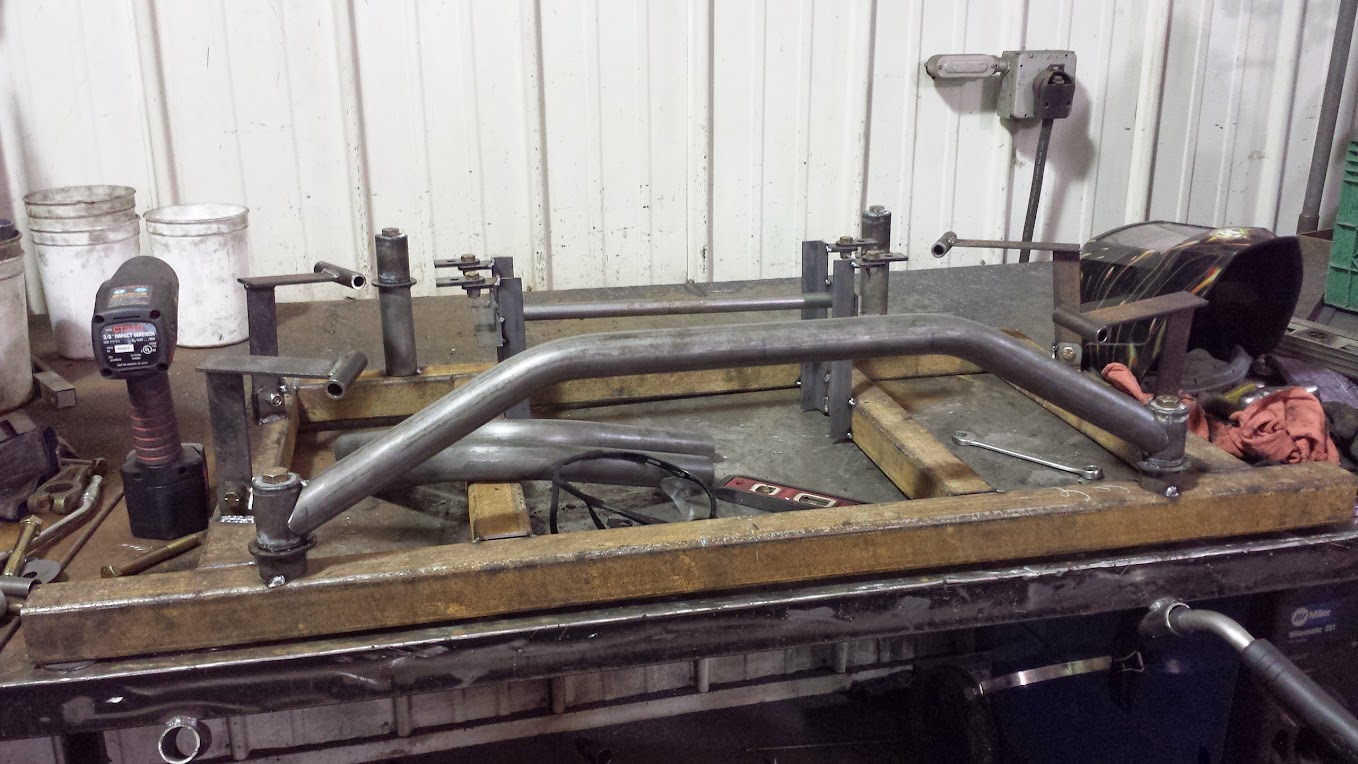

Audi S2 (D M Developments, tubular)

MKIV VW, F M Fab (Canada, CAD vs. USD):

Reply With Quote

Reply With Quote

Because you alter the metallurgy and the designed in safety.

Because you alter the metallurgy and the designed in safety.

Bookmarks