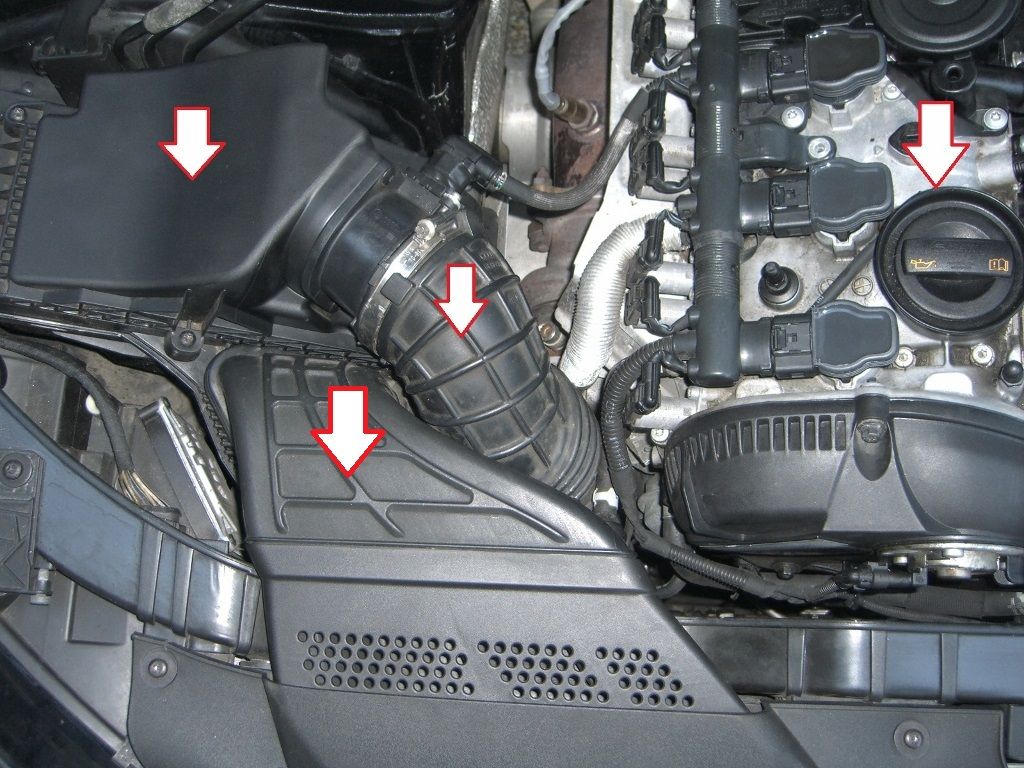

Start by removing the air scoop that feeds the airbox. Disconnect the MAF. Loosen the clamp on turbo inlet hose. I remove the airbox as well, it just lifts out. With the airbox out of the way remove the lower clamp from the turbo inlet and remove the inlet. Remove the oil fill cap, if pressure does get by the seal we will install in the turbo you want it to vent.

Remove the hose from the throttle body

Remove both foglight surrounds. A flat blade screwdriver inserted in the slots and release the tabs (these break easily) to remove the surrounds This gives you access to the intercooler connections for later inspection. If leaks are found you may have to remove the front bumper. Here is a great DIY on that by Scottish_A4.

http://www.audizine.com/forum/showth...?highlight=DIY

Here you can see the difficulty in sealing the turbo inlet. The port in side of the turbo inlet is where crankcase vapor is feed into the intake while you are in boost as this area is always in vacuum(with engine running).

I choose to pressurize my intake lines using an air compressor. So I setup my cap with an air fitting. If you don't have a compressor, a threaded schrader valve (car tire) and a bike pump will work. Very large leaks will be hard to pressurize with a bike pump but leaks you may still hear it. I suppose it possible to use a can of keyboard duster (look for a nonflammable kind). I started with a 2" pvc pluming cap. I just drilled a slightly smaller hole than my fitting and let te fitting cut its own threads. You could easily go slightly larger and use epoxy as well. You will find it easer to install the cap later if you camfer the lower edge .

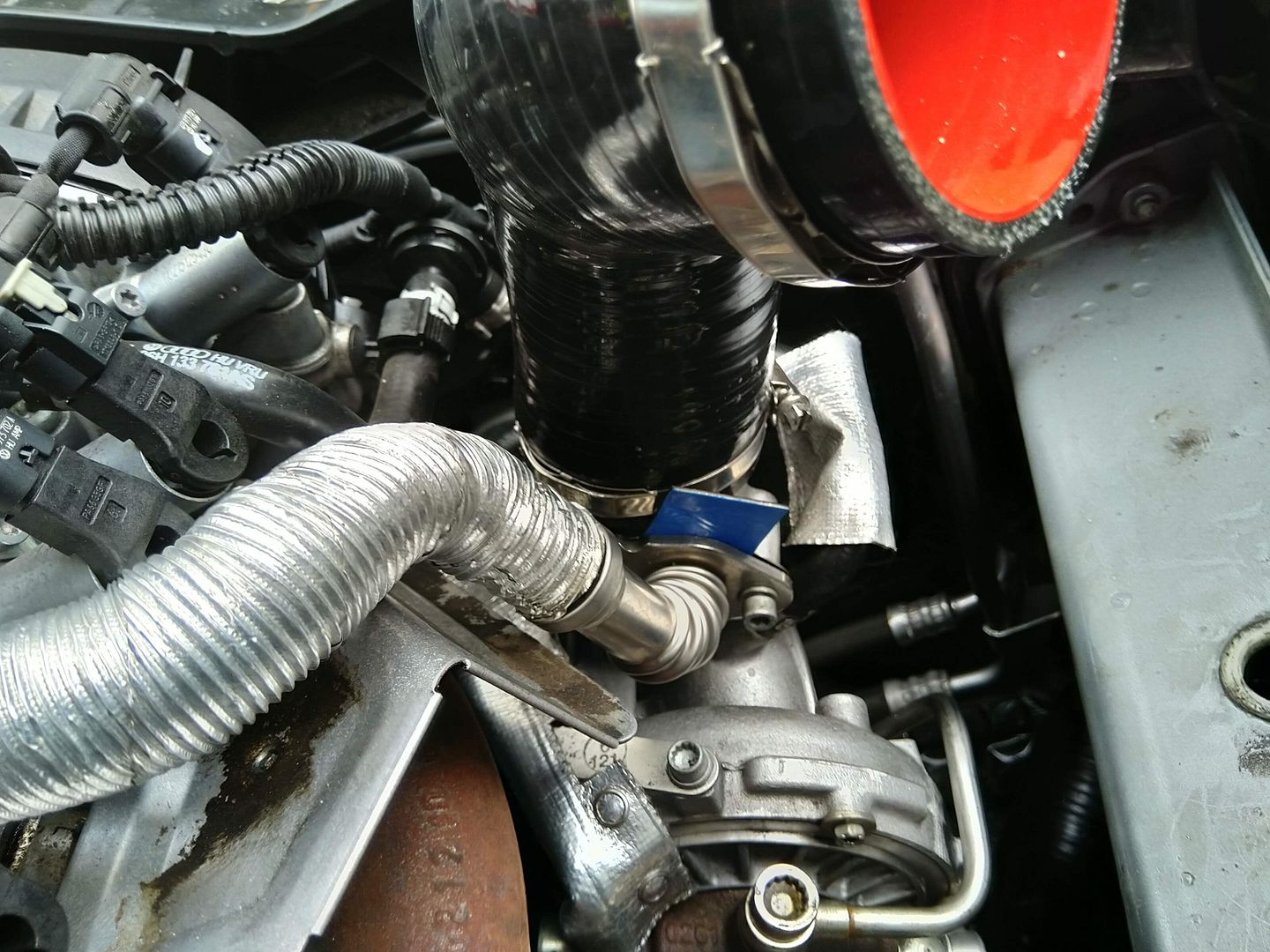

To plug the turbo inlet I used a bike tube Look for around a 2" diameter(i.e 26"x1.95"-2.1"). Cut the tube leaving around 10 to 12 inches each side of the valve stem. On one side tie a knot as close to the stem as you can. Tie the other knot about 5 inches away from the stem. Remove any extra material beyond both knots. Clean the tube with alcohol or soapy water and let dry. Barely inflate the tube so it just takes a natural shape (this will be very close to your turbo inlet size. Loosely wrap the tube in electrical tape from the knot closest to the stem to about 1 inch above the further knot. You only adding some reinforcement to the tube. This will cause the un-taped portion of the end to expand more and form a slight mechanical lock inside the turbine housing.

Here it is installed. Install the sealing plug and inflate until snug.

I have a compressor tank full and the compressor turned off. I verify there is no air pressure in the line and connect it. I slowly open the regulator until I just hear air entering. Give it a few seconds to pressurize the lines. I start with approx 3psi. this setup runs very quiet and makes it easy to hear any leaks. take a bottle of soapy water and starting spraying down areas and look for bubbles. The DV will be charged equally on both sides of the compressor housing so you should be able to check for leaks around its base as well. If you have no leaks it will be very quiet and it may hold air if you close off the line to the regulator (it may leak off as these fittings rely on higher air pressure to help maintain their seals). This method you cannot apply a full 20 psi as the plug in the intake will be shot out like a small mortar. You might get 7 to 10 psi at best, which will find most leaks using soapy water. Its a good idea to lay a towel over both air fitting in case they pop out. Its a wise idea to have an 8mm socket and a flat blade screwdriver in your car the next day or so in case you missed tightening a line back up.

If you suspect a leak thru the intake manifold via a faulty PCV this is an easy test. With the engine off. Remove the hose from the intake manifold by depressing the upper and lower ribbed areas. It will slide out.

Cover the intake port with a plastic bag (a thumb cut off of a nitrile/latex glove works well). Overwrap it in electrical tape. Put some stretch on the tape when wrapping to make a good seal. this will reinforce the bag as well. If you plan on leaving this on for a longer drive a ziptie or hose clamp may be order as under hood temps weaken the tape adhesive. Put the roll of tape and an extra bag in car just in case.

Go for a drive and see if your boost loss is gone. The PCV can still vent to atmosphere as well as thru the turbo inlet. Its not pretty, but its a lot cheaper than buying a PCV because you guessed wrong.

Reply With Quote

Reply With Quote

Bookmarks