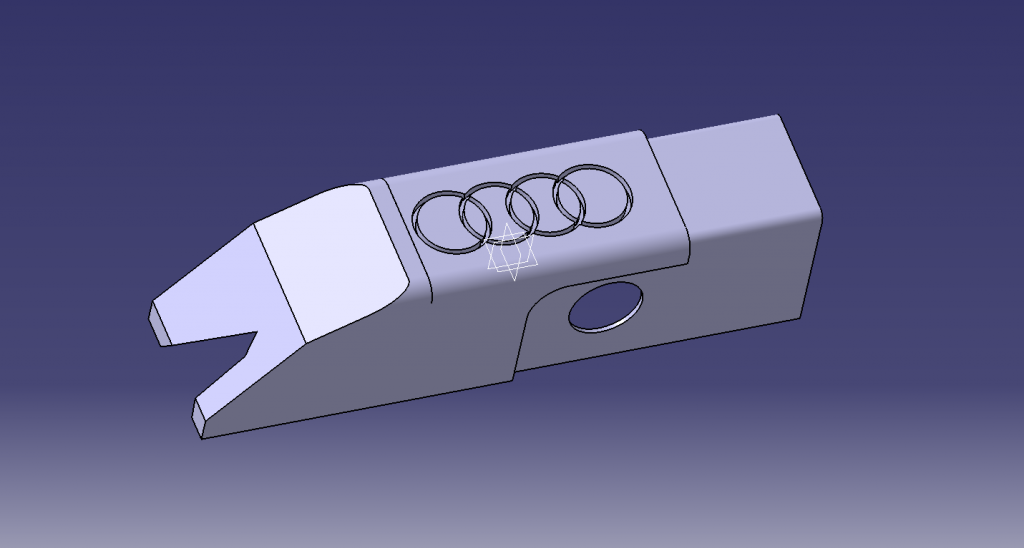

So only thing to do is make them fit! Right? Just so happens my career enables me to 3D print and create cad designs.. after modelling the arm end and new wiper profile i managed to create a nice enough piece that would enable me to get these nicer looking wipers connected and below is a pic for you all to check out.. and of course i will pass the cad file and/or 3D print file to anyone who may be interested.

Any more of you guys have CAD designed retro fit parts like this you want to share get some images up it would be interesting if we could put a list together for users.

This works in conjunction with a small bolt/nut through the visible hole and the holes already on your wiper arm, it is very easy to install the wiper as it slides in and will not release unless you remove your bolt.

Wiper aero fit link Clicky

Reply With Quote

Reply With Quote

| RA4 Stage 1 w/SMFW | Milltek | Uni HFC/3'' DP Combo | 3'' TIP w/MAF | 550cc | TR1.8 FMIC | USP F/R | H-Sport F/R Sway | APR Snub | RS4 Motor Mounts | Stern Trans Mount | Skid Plate | Solid Tie Rod Ends | Short Shifter | Euro Shift Knob | VMR Boost Gauge | S4 F/R Brakes | Tyrolsport Stiffening Kit | ECS S.S. Lines | Hawk HPS Pads | 034 PCV

| RA4 Stage 1 w/SMFW | Milltek | Uni HFC/3'' DP Combo | 3'' TIP w/MAF | 550cc | TR1.8 FMIC | USP F/R | H-Sport F/R Sway | APR Snub | RS4 Motor Mounts | Stern Trans Mount | Skid Plate | Solid Tie Rod Ends | Short Shifter | Euro Shift Knob | VMR Boost Gauge | S4 F/R Brakes | Tyrolsport Stiffening Kit | ECS S.S. Lines | Hawk HPS Pads | 034 PCV

:

:

Bookmarks