Originally Posted by

zandrew

Quattroginger- The other person I know running the Franken runs the United 630cc tune that uses the VR6 MAF and he is happy. He says its not perfect but runs good and pulls hard. He went with it so he could upgrade to a GT28 without issues.

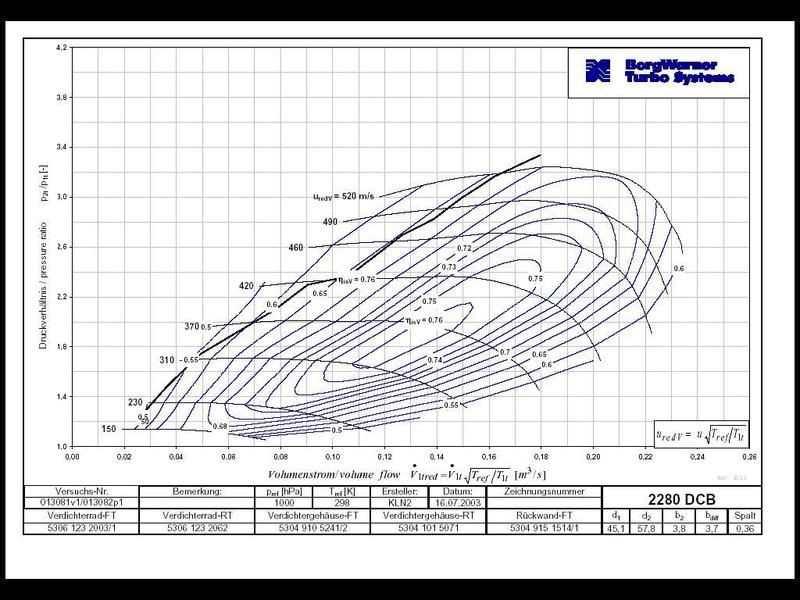

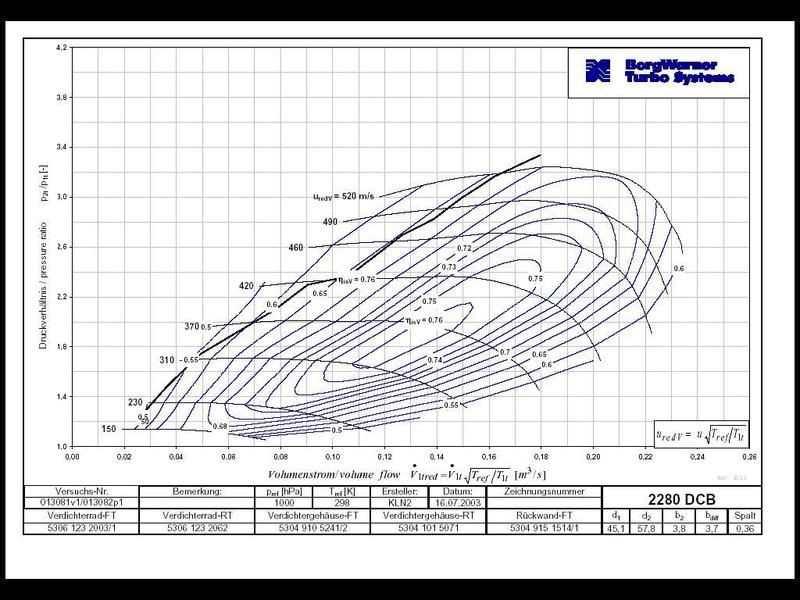

Zimbu- Here is the compressor map directly from Borg Warner. Giggity.

It is the 2280 compressor. Take 22 which is inches and times by 25.4 to convert inches to mm. That is 55.88mm (they like to round). Then take that times .8 (the 80 stands for 80%) and you get the compressor inducer. It is 44.7mm. Funny they don't add the exducer extended tips. The m3/sec does come out right around 34lb min. I think what I did last time was convert to cfm and then lb min. .235 m3/sec is 540 cfm. 540cfm x .069 (factor I picked up from turbonetics) equals 37.26 lb min.

I think I read some of your old posts hating on billet compressors saying they were snakes oil. It was in a thread I was comparing the highest whp 1.8t AEB to the highest whp 2.0 AEB (funny since the 1.8 actually made almost 300 more awhp and in the same rev range as well but I chalk that up to turbo). You don't think the newer billet compressors actually make more flow?

Yep, like I said, it's a 2280 just like the Mazdaspeed's sompressor. IIRC, the next size up used on the F-23 was the 2283.

As for my thoughts on billet compressors, I'm not completely hating on them. Fact is, most of the billet compressors they are using flow better than the cast ones that they are replacing. My problem is that companies are selling them as being better simply because they are made from billet Aluminium. As far as I'm concerned this whole "it's better because it's lighter and the fins are narrower" stuff is complete horseshit.

What makes them better is the aero profiles on the compressor are better. However that has nothing to do with them being made from billet blanks, it's because until recently (with the exception of lines like the Garrett GT series) most performance turbos were basically derived from the parts bin of commercial applications.

Why? because until recently, it was prohibitively expensive for a small manufacturer to invest in designing compressors using castings. However, with the advent of cheap 5 axis machining, small companies can get a design that they think is close, make one-offs on the 5 axis machines and tweak it until they get it right.

The only inherent advantage I see in billet compressors is that I do think it allows for a smaller root hub and therefore more blade area vs the comparatively wide hub that a cast wheel tends to have.

However the fins are no smaller than a cast compressor. Hell, I measured my Comp turbo fin thickness and my comp billet wheel is way thicker than my old 60-1 I was running. In fact, the 60-1 fins are like paper. Also, I feel that the weight savings vs a cast unit would be negligible at best. You know as well as I do that unless you're running an EFR turbo that the turbine is by far the heaviest part of the rotating assembly. Also, you know as well as I do that the turbine is really what dictates your spool-up. The compressor creating pressure is the byproduct of getting that turbine spun up first.

So really, my biggest problem is when companies use questionable logic to try and hype their product. If there is a real advantage then by all means advertise it. However when I see some of the claims that are made using logic like "it spools faster because it has thinner blades etc..." it just makes me think that these guys really don't know what the hell they're talking about. That, or they're just plain shady and will say anything to get you to buy their stuff.

Reply With Quote

Reply With Quote

Bookmarks