Yes, how i still own this car is unknown. I havent been on here in what seems like forever. So I have 2 burned out ballasts. 1 is a "spare" (kind've...its dead, but i hadnt thrown it out), the one that just died is still in the car and i have only 1 working one. The only information i could find about these fucking things were on Russian and German forums...IIRC, 3 or 4 of them. So while pages were tanslated, i tried to make sense it all, even though some slang thats used...google translate doesnt know what it is. I certainly seem to be the ONLY person in the states to have at least made a DOCUMENTED attempt to fix one of these overpriced things. There was one other thread but it was left to die. :(

To sum up the findings, theres an IC inside the ballast housing, on the board, that just dies and can be replaced. I guess this is assuming that there isnt any other water damage on the board (top o bottom). Thing is, its not a fun replacement.

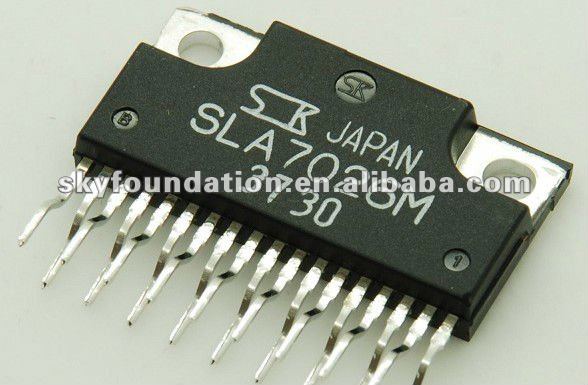

Heres the IC in question:

My entire board looks new still, theres no visible water damage, corrosion, etc, nothing.

this is what the LAD5G looks like underneath (not mine):

ive ordered 2 new IC drivers on ebay (theyre about $4 +$4 shipping, each...yeah, way cheaper than $100+) and will most definitely report back my findings. Wish me luck.

I received a notification from the ebay seller late last night that the 2 new IC's have shipped...so itll probably be about 2 weeks before i even get them, but i got things started anyway.

Using a heat gun and aluminum foil, i removed the OE IC from the PCB.

the trick is to wrap aluminum foil over EVERY part of the ballast PCB EXCEPT the IC area to keep the heat minimal everywhere else but the IC.

I used a hobby knife, dentist tools and a small sharp flat head screwdriver to assist in the removal. the flat head worked great at getting the body of the IC up off the board (its soldered there too, thin layer under the entire surface.)

SO i received the new IC's today and immediately go to work...since work was slow..i had some time, heh.

using copper wire solder braid, suck up the remaining solder left on the board from IC removal. I used a nice weller vacuum soldering iron i have at wok for this. This is done to make sure the IC lies flat on the PCB surface.

Line up the pins and use something to hold it in place..i used shitty scotch tape that was on my desk. (mine ended up moving slightly anyway...so its a LITTLE crooked.

First row done

second row

and i think this is where someone had some trouble on one of the russian sites was getting the rear of the IC attached to the board...and it is hard to get solder in there to stick to ALL of the surfaces...i did my best and its tricky...

i just tried to get the corners...as previously the entire bottom of the IC was seated to the board.

I will give it a shot tonight and see what happens..wish me luck.

If nothing happens ill bring it back to work and suck everything up from the 2 corners and try again...like i said, apparently thats the tricky part.

Reply With Quote

Reply With Quote

| RA4 Stage 1 w/SMFW | Milltek | Uni HFC/3'' DP Combo | 3'' TIP w/MAF | 550cc | TR1.8 FMIC | USP F/R | H-Sport F/R Sway | APR Snub | RS4 Motor Mounts | Stern Trans Mount | Skid Plate | Solid Tie Rod Ends | Short Shifter | Euro Shift Knob | VMR Boost Gauge | S4 F/R Brakes | Tyrolsport Stiffening Kit | ECS S.S. Lines | Hawk HPS Pads | 034 PCV

| RA4 Stage 1 w/SMFW | Milltek | Uni HFC/3'' DP Combo | 3'' TIP w/MAF | 550cc | TR1.8 FMIC | USP F/R | H-Sport F/R Sway | APR Snub | RS4 Motor Mounts | Stern Trans Mount | Skid Plate | Solid Tie Rod Ends | Short Shifter | Euro Shift Knob | VMR Boost Gauge | S4 F/R Brakes | Tyrolsport Stiffening Kit | ECS S.S. Lines | Hawk HPS Pads | 034 PCV

Bookmarks