Hi All,

Below is my attempt at a spark plug replacement DIY that I ran this weekend.

I based this off of the DIY for the B7 spark plugs found here:

http://www.audizine.com/forum/showth...te-for-B7-A4-s

Required tools/components:

- Torx Screw driver/bit - getting size

- Flathead (wide) screw driver or Swiss Army knife (short throw is best for short lever arm - minimizes force)

- Socket wrench

- 5/8" spark plug socket head

- 10" socket wrench extension

- Torque wrench (will add size/type)

- Gap measurement tool (see far left in picture below)

- 4 spark plugs

As far as the plugs go, there have been 2 recommendations from APR:

- NGK PFR7S8EG @ 0.028 - APR recommended for those at Stage 1/2

- NGK PFR7B @ 0.028 - APR recommended for those at K04

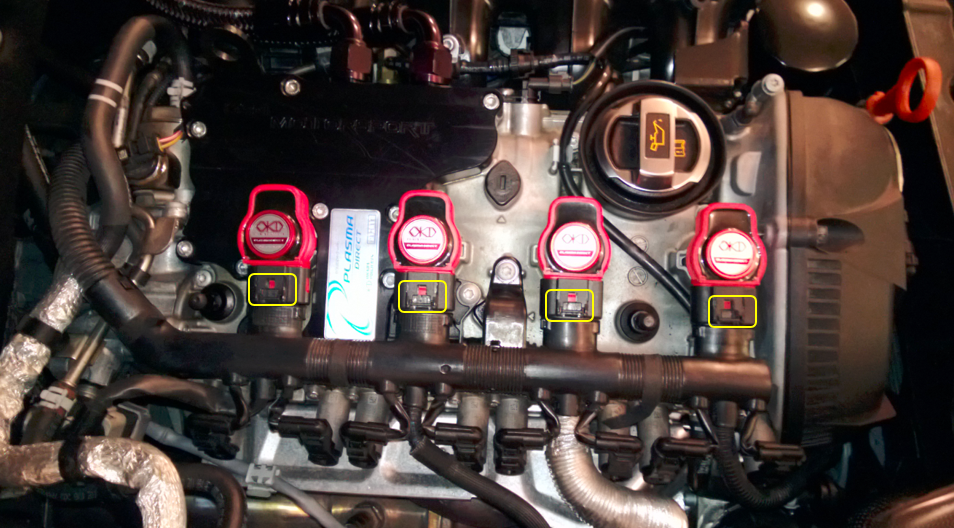

Step 1: Remove engine cover and locate your coil packs. OEM are black. Mine are aftermarket Okada red plugs. There are 4 in the 2.0T engine.

Step 2: Unscrew the 1 screw in the picture with your torx screwdriver or bit. I recommend doing this only with hand strength (no drills, etc.) so as not to strip the head.

(Please ignore the fact that the plugs are already out in this picture - LOL late shot)

Step 3: Using a wide flathead screwdriver (or the wide flathead bit in a Swiss Arm knife) insert above the clips in yellow and gently pull towards the turbo. You will hear a tiny pop/click. Stop immediately.

If you pull too hard, far or fast you will break the plastic. Heating the parts up a touch with a blow dryer will also make them a bit less brittle, but is not necessary.

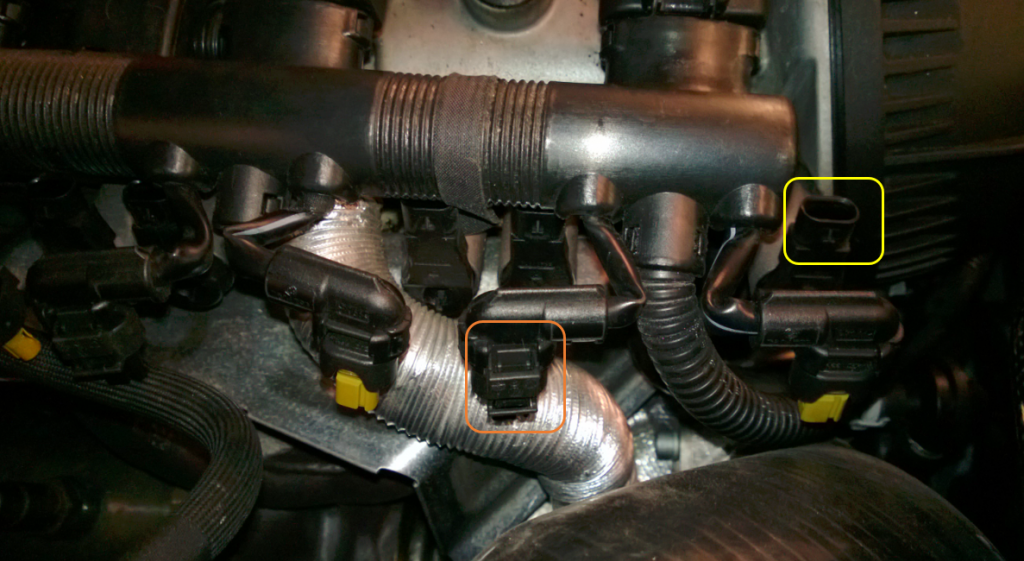

Step 4: Uninstall the 2 plugs behind each coil pack connector. They are relatively small with a retention clip midway down from the top of the head, but you can slightly depress with a screwdriver and pull up gently.

They come out with very little force. Try wiggling lightly while pulling up.

Step 5: Gently pull back the entire harness knowing it will pivot from deepest into the engine bay (I think Cylinder 4) just enough to get to off the Coil Pack plug socket. Pull out the housing sockets from each plug gently while doing this.

Step 6: Pull coil packs vertically up and out. Try to grab directly around the head, avoiding pulling on the actual plug connector as the plastic walls are thinner there and could warp/crack. Pull normal to the plug (meaning you'll be pulling up and out at the same angle as the plug is pointing and not straight up to the sky). This will take some force. Wiggling as you go gently also helps. When they do release, they come out with a pop, so try not to go flying backwards or letting go and sending them flying.

Step 7: Take a peek in the holes. You should now see your spark plugs. Ok - gratuitous pic with my Windows Phone 8 Nokia 920. Amazing camera!

Step 8: Attach the 10" arm and 5/8" spark plug socket head to your socket wrench and insert gently down into the plug cavity. Place the head around the 5/8" mating surface of the plug and rotate gently until firmly in place. Begin twisting counter-clockwise to loosen the plug.

Note - you may feel no resistance or little. If so, lift up slightly and reseat the socket. Eventually you'll feel significant resistance. Go slow when loosening and take your time.

Step 9: Remove each plug one by one and match with the coil packs as they came out. (Obviously you'll throw away your old plugs later or keep them (I am) to compare change over change).

Step 10: Once the plugs are removed, double check the gaps on your new plugs to ensure 0.028. You can use the feeler gage/gap tool to measure this. If the gap is too small, open with the gapping tool (pic above). If too wide, gently tap the head on a clean surface to close. (Not very scientific).

Step 11: Load the new plug into the 5/8" spark plug socket on the end of the 10" extension. Do not use the socket arm. You want to finger tighten the plugs first to make sure you don't cross-thread or bind. When inserting back into the plug socket, go slowly and ensure you aren't banging the walls on the way down. Insert/align gently at the bottom where the threads meet and finger tighten until firm. If you feel it is angled, cross-threading, etc., stop, pull the plug up and reseat.

Step 12: Finish installing all the plugs, then attach a Torque Wrench to the top of your 10" extension + 5/8" spark plug socket and set the wrench to 15-18 ft./lb. of torque. Rotate to tighten until the torque wrench clicks. Repeat on the 3 other plugs.

Step 13: Now perform the final torque by setting the wrench to 22.1 ft./lb. of torque and tightening until the click. DO NOT tighten any further than the first click.

Step 14: Reinstall each of your coil packs in the same cylinders they came out of. Make sure they install all the way flush to the housing and are aligned properly. There are small plastic alignment features on the plug to help you see/feel this. Press in firmly.

Step 15: Reinstall the 4 coil pack plugs on the OEM wire harness to the coil packs until they click in firmly.

Step 16: Reinstall the 8 connectors (2 per coil pack location) on the opposite side of the OEM wire harness until each clicks in firmly.

Step 17: Reinstall the 1 torx bit screw back into the engine block to pin down the OEM wire harness.

Step 18: Pat yourself on the back, cross your fingers and start-up your engine. If any thing sounds weird, you may have missed a connection or have a bad plug. Shutdown immediately and verify.

Step 19: Enjoy a BEvERage of your choice. You just saved $50-$75 at your dealer at least.

Here are my OEM Bosch plugs at 31K miles. I forgot to measure how they were gapped, but OEM is supposed to be 0.032:

New ones (NGK PRF7B @ 0.028):

|VCDS|Love the VAG 4Bangers unless it eats oil|EurotechMS

Bookmarks