This DIY applies to, of course, my 2003 B6 Audi A4 Avant 1.8T AMB motor - I know the AMB longitudinal 1.8T in the Audi has this sensor, and I'm sure it applies to other models as well. This is strictly a guide, do your research and get the correct parts for your application.

This task will probably will take about an hour from start to finish. If you do it when changing your oil its about an additional 15 mins. or less, which is simply the time it takes to change the sensor out after draining your oil.

First thing you will see is the yellow oil can icon with the word "SENSOR" in your DIS:

Scan it, and you won't see a code. Or at least I didn't, so I understood it was a mechanical problem with the sensor. I went with the Meyle OEM replacement, which is a German part, but ironically has a Made in China sticker on it :\ Well, it's half the cost of the real VAG OEM part, so I'll give it a try:

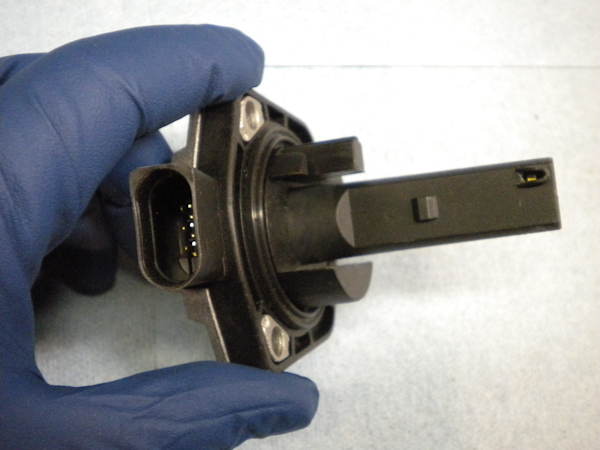

Here's a couple of pictures of the Meyle replacement:

So onto the DIY part - If you still have your splash guard, remove it. Drain your oil. I decided to drain my existing oil into a clean gallon milk jug with the top cut open for easy filling. Some may ask why, I run Amsoil, which was recently changed and will last longer than most synthetics, and it's expensive. So I wanted to save it until the next time to change, which is in a couple more thousand miles. You may opt to do this on a regular oil change:

From there, you will see the sensor bolted in the oil pan. Remove the sensor connector (already unplugged) and unscrew the three 5mm hex bolts. Then simply pull the sensor down and out of the pan. Keep the black metal cover and save it - it will be used on the new sensor:

Old and crusty, pics to compare to the Meyle part. Pretty much the same...I would suspect they are more than likely made in the same factory:

Thoroughly clean the sealing surface of the oil pan in prep for the new sensor install:

Clean up the bolts and the metal cover:

Installation is the reverse of removal of the old sensor. No additional sealant is needed, the rubber o-ring is double lipped and is more than adequate. Torque each bolt to 10nm (Thanks Johnny Quattro) - don't over-tighten, or you will be replacing your oil pan. Plug the connector back in to the sensor, and the job is done:

Torque info added from Johnny Quattro

Reply With Quote

Reply With Quote

Bookmarks