Just wanted to say "Thanks !" for all the tips on this thread.

I just did this TWICE on my car.

Apparently the o-ring got pinched the first time, it leaded and had to do it again. Unfortunately, the o-ring was broken when I pulled the flange out so I had a delay while trying to locate someone who sold the o-ring. Since it is Sunday, the Dealer is not open and the parts department is closed tomorrow for Memorial Day. Arghh...

Autozone, Advanced Auto, O'Rieley Auto, NAPA ... none of them carry the flange or the O-Ring. I bought an o-ring kit from Harbor Freight ($7.99) and used one from it. The kit has 3 hundred something O-rings in the kit. It has 10 of the size I ended up using, so I now have spares. :) I was a little worried about using one from Harbor Freight, but it is a Nitrile Rubber O-Ring, same description I saw for similar o-rings on car coolant systems. I think I am safe. Took a 50 mile test drive, and things are good so far.

Here are my tips/lessons learned from doing it TWICE !!!

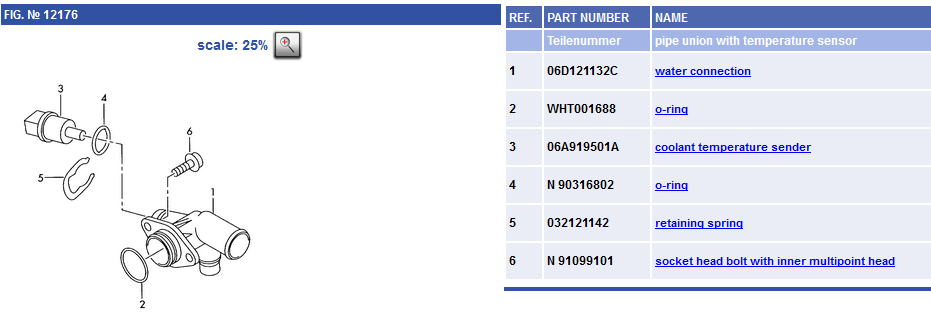

Do not underestimate the comment some have made that the rubber hoses might be WELDED to the metal pipe. I spent over an hour trying to get the "lower coolant hose" off. That thing ended up tearing, but not releasing from the pipe. I finally cut it off and was able to get the metal pipe and flange out. The short hose between the pipe and flange came off my flange easily. I spent about 30 - 45 minutes taking a razor blade to clean the bits of rubber off the other end of the metal pipe where the lower coolant hose connected to the other metal pipe. I spent a lot of time cleaning that 2nd metal pipe off too. I think Audi must have used epoxy or something similar to glue that pipe and hose together. The other locations that I removed hoses from came off easily. So, the lesson learned, if you are the first to do this job on your car, buy that piece of hose, and just CUT OFF the original. The hose part # is 06D121065L. It is part #4 in the below image.

I had an old broken down cardboard box in the garage. The 2nd time around, I laid it on top of the engine and down the front of the grill. I spent a lot of time laying on top of the engine to get to the back where the flange is located. The double layer of thick card board really make it a lot easier on my ribs and stomach, and also probably helped protect stuff I was laying on. That made it SO MUCH more comfortable.

Definitely remove the Vacuum Pump. It is ONLY 3 hex bolts and one hose. With it removed, you can so much easier get your hands down to the flange. Plus it will almost let you see it.

Remove the wiring harness from the iginition coils, HP Fuel pump, and disconnect the little plastic pieces holding that harness to the engine. This will allow that harness to drop completely out of the way and frees up a lot of room.

My coolant flange was held in place w/ T-30 Torx bolts, NOT triple square fasteners.

A dental pick that has a "U shaped" end will easily grab the metal clip from the lower hose and the plastic clip for the temp sensor.

If you pull off the belly pans before you start, you can drain the radiator into a pan to recover the coolant PLUS when you drop something, it falls all the way to the floor. I left my car up on the ramps, so that left enough room for me to get under and pick up the random bolt or tool. If I had left the belly pans on and the car on the ground, I am sure locating a couple dropped items would have really taken a while to locate.

I used Quicksilver "Perfect Seal" sealing compound everywhere that I connected a rubber hose. I have been doing this for many years now. First learned about it when working on my first boat. The stuff is almost like a syrup. It does not harden or dry out. It is recommended by Mercury Marine and Mercruiser (same company, really) for all hose connections on marine engines. I do not see how it would not be a good idea on car engines too, so I have been using it. Since I have a bunch left over from my boat, it doesn't cost me anything to use. I think it will prevent the "welded" on problem with the rubber hoses to the metal pipe. I am not sure of an automotive equivalent, but inboard marine engines are actually just truck gas or diesel engines w/ a propeller.

Reply With Quote

Reply With Quote

Bookmarks