Everyone, please contribute, i know some of you guys here are fittings/lines gurus! the more info the merrier :)

--------------------------------------------------------------------------

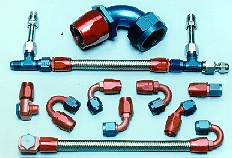

Fitting/hoses assembly DIY's

http://www.dsmtuners.com/forums/arti...-fittings.html

http://www.honda-tech.com/showthread.php?t=2150049

http://www.club3g.com/forum/performa...-fittings.html

*******

Holley.com - an excellent catalog/resource site for Earl's brand.

*******

Places to buy from: (i don't know which brands are better quality, so folks please speak up!)

Summit Racing

Jegs

ThinkAuto

American House

Baker Precision

034 Motorsports

ATP Turbo

Russell Performance

Pegasus Auto Racing

*******

If you're looking for black AN fittings

*******

An always useful Wiki info :)

AN/NPT Fitting Thread Size Chart

“AN” THREAD SIZES

AN (Army-Navy) Sizes were established by the Aerospace industry years ago and were designated O.D. of the rigid metal tube that each size fitting is used with. (The chart to the right will clarify this point.)

The numbers assigned equate to the O.D. (outside diameters) of the tubing in 1/16”. Since tubing and hoses are to be found with assorted wall thicknesses, we can now understand that the designated size number does not necessarily tell you how large the inside diameter will be. (For example, the inside diameter of an Earl’s size 6 hose end is nearly as large as the inside diameter of some manufacturers’ -8 hose ends.)

Each AN size number has its own standard thread size which can be seen in column three of the chart. Again, these are the same thread sizes that have been used in aircraft and industrial applications for many years.

“NPT” THREAD SIZES

Some of the most popular adapter fittings shown in their catalog are AN to NPT adapters. While many variations are offered, column four in the chart shows which AN size corresponds to each NPT size when inside diameters (flow dimensions) are considered.

All Earl’s Swivel-Seal hose ends are designed to provide little or no restriction when used with the corresponding AN fitting size. We also offer a number of Metric and British Standard Pipe threads to AN fitting adapters.

******

Excellent PDF doc depicting all different types of the available fittings

Different available fittings/hoses and their application (info is from thinkauto.com)

Aerospace Style Hoses

For war zones like Vietnam the US military required a range of strong, light, high temperature hose assemblies that could be serviced in the field for use in oil, fuel and hydraulic applications, mainly on helicopters. Aeroquip came up with the AE701 hose and "Little gem" ® fittings, these eventually found their way onto the war surplus market and were seized upon by the motor racing fraternity.

The supply of these hoses and fittings gradually dried up, and a new industry came into being making compatible hose and fittings. Earls "Permo-o-flex", Goodridge "200" and Keith Black "Kb-plus" are examples. Aeroquip returned to the market with the hose renamed "FC333 Racing hose".

All these hoses and fittings are interchangeable but only assemblies from one "manufacturer" have any guarantee. Despite the interchangeability there are differences in design of the method of fitting and the means of achieving a "double swivel" on angled fittings.

In the beginning the Aeroquip " little Gem " fittings had a cutter style attachment. which was suited to coping with the high pressures in hydraulic systems and assembly by trained personnel. For the less demanding motorsport use they opted for the far more user friendly compression style fitting, unlike the competition which stayed with the old design.

Aeroquip were very late in producing a double swivel angled fitting but when they did they overcame problems associated with existing designs where to achieve a swivel the fitting had to turn in the hose thus breaking the primary seal and often when sticking occurred the secondary seal as well.

Complies with FIA regulations. Used by professional teams who will only consider the best for fuel, oil and airjack systems.

MOQUIP aero hose & compact fittings

AEROQUIP racing hose & fittings

Moquip Oil Hoses

Moquip oil hoses and fittings are economically priced and suitable for all oil carrying purposes in vehicles except those used in competition where regulations specify a 135°C maximum temperature. (The hose will still function at these temperatures but a gradual but detectable hardening of the hose will shorten life).

Aeroquip push-on hose & fittings

This is a textile hose with synthetic rubber inner tube, one layer of textile braid reinforcement and a synthetic rubber outer layer.

Assembly of hose to fitting is very simple, the fitting is simply pushed into the hose, this hose has the reinforcing braid woven in such a way that the grip on the fir tree type fitting increases as the force trying to push it out increases.

This hose has had a resurgence of popularity recently, especially since aluminium fittings were introduced. Some examples of this hose have a 150°C rating, however instances of the fitting blowing out of the hose at extreme temperatures have been reported on some makes (not Aeroquip), extra clamping should be considered where very high temperatures are involved.

This type of hose and fitting can be interchangeable between brands but only genuine Aeroquip assemblies can be guaranteed. We can provide a stainless steel braid covering for these hoses, this does not impart any greater strength only enhanced appearance and abrasion resistance, factory swaged ferrules or finisher such as a “Pro clamp ® “ must be used to hide frayed ends.

Smooth bore TFE hose and fittings

Conventional brake hoses, manufactured in rubber with textile reinforcement, are permitted to have a significant amount of volumetric expansion, that is they swell under pressure, this leads to a soft feel to the brake pedal, acceptable in a road vehicle but not for competition.

On racing vehicles, this has lead to the universal usage of smooth bore PTFE (Teflon ® ) hose with normally a stainless steel. This hose has the added benefit of lightness, strength, high temperature resistance and protection from stone damage.

We call it " Moquip TFE ", Aeroquip " TFE racing hose " or " 2807", Aeroquip Aerospace " 666 ", other brand names are " Speed-Flex ", 600 ", and " 411 ". They can be had with re-useable or swaged on fittings. With the exception of Aeroquip Aerospace, hose and fittings are interchangeable between brands.

Some countries, not the UK, insist on tests for brake hoses. The TFE hose assembly passes all the tests except the whiplash test which ensures that the hose is suitable for withstanding large wheel movements on vehicles doing hundreds of thousands of miles, quite sensible, but not relevant to competition motoring. Some hose specialists have recently come up with complicated assemblies allowing the hoses to pass the test, but generally speaking, they are not suitable for high mileage road usage.

These hoses are also suitable for oil pressure gauge lines, fuel injection pipes, power steering hoses and, because of their high temperature capabilities, on turbocharger oil feed and return lines.

Aeroquip Startlite hose

Use where light weight is a primary concern. Complies with FIA regulations. Very little heat dissipation through hose which can be handled whilst containing oil at 100ºC. Unlike convoluted TFE hoses, hose bore is smooth.

The hose has a special AQP neoprene inner tube, reinforced with fire retardant Nomex outer. To achieve greatest weight saving, up to 45%, use factory swaged silver and blue fittings, for on site assembly use the red and blue compression style Racing Hose fittings.

Convoluted stainless steel tube and fittings.

Specially formed stainless steel convoluted tube with re-useable red/blue anodised aluminium fittings. Use on fuel lines, dry sump lines to and from tank where light weight and ease of installation are considerations.

ProGold hose & fitting

An extremely light hose assembly consisting of a convoluted wrapped PTFE (Teflon) liner with a Nomex covering, PTFE hoses are resistant to all types of automotive fluids. They are also available with stainless steel braid outer covering. Where the utmost weight saving is sought factory swaged fittings are used but hoses with re-useable fittings still offer a significant weight saving. There is no interchangeability of hoses and fittings between different manufacturers of convoluted TFE hose.

Fittings are aluminium with anodised blue fittings and gold nuts/ferrules. Elbows have one piece bends (not brazed) and the double swivel rotates in the housing not hose. ProGold AR fittings are reusable, ProGold AC fittings are swaged at our factory.

There's a huge amount of different adapters that could be used with AN fittings and all could be purchased from any of the sources above.

cont. next post.

Reply With Quote

Reply With Quote

Bookmarks